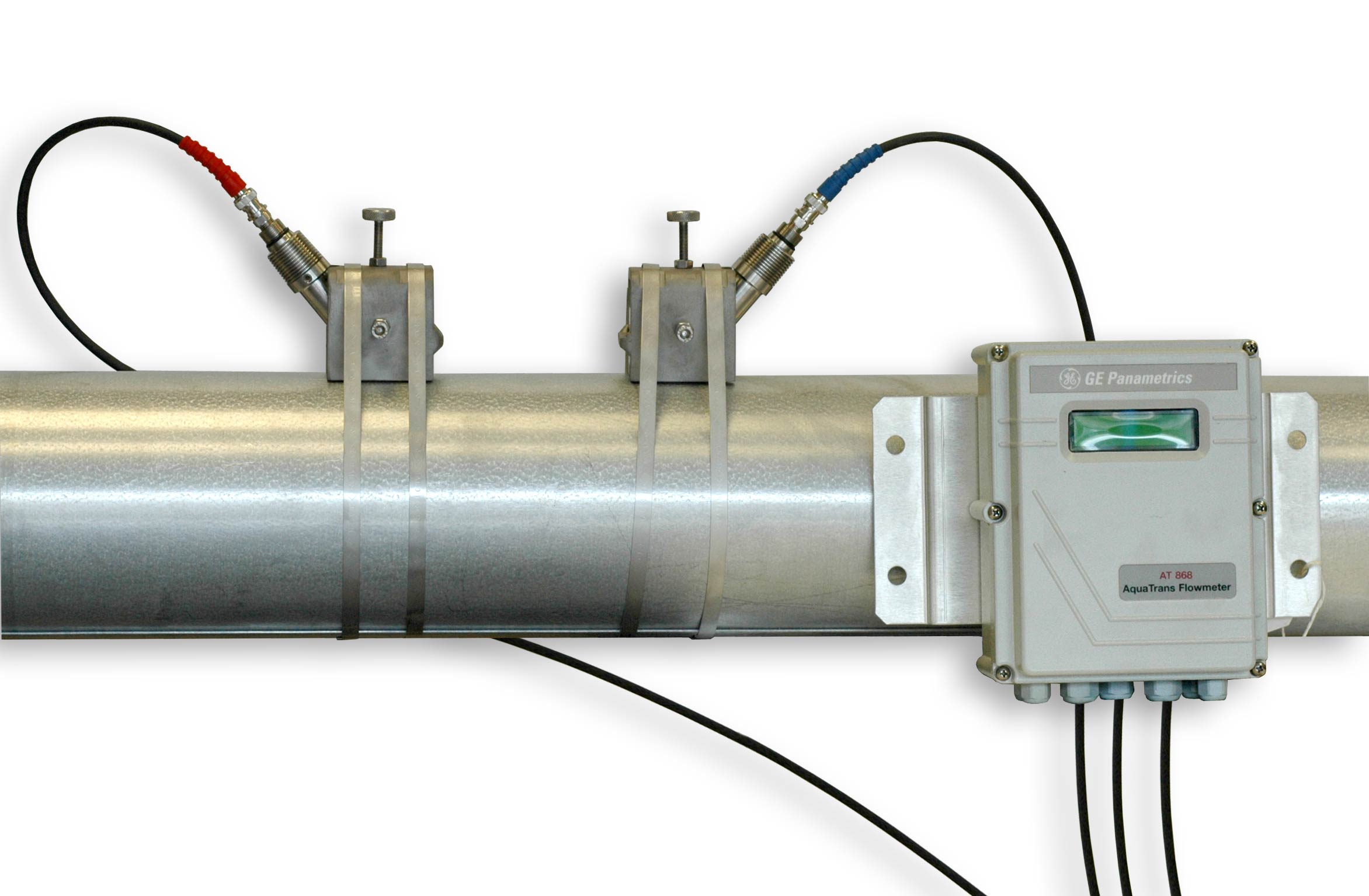

AquaTrans™ AT868

Panametrics liquid flow ultrasonic transmitter

Applications:

The AquaTrans AT868 liquid flow transmitter is a complete ultrasonic flow metering system for measurement of:

- Potable water

- Wastewater

- Sewage

- Discharge water

- Treated water

- Cooling and heating water

- Other liquids

Features:

- Economical non-intrusive flow measurement

- Simple setup and installation

- Suitable for wide range of pipe sizes and materials

- Suitable for lined pipes

- Two-channel/two-path version available

- Velocity, volumetric and totalized flow

- Internal keypad for field programming

Liquid flow ultrasonic transmitter

The AquaTrans AT868 liquid flow ultrasonic transmitter combines state-of-the-art flow measurement capability with a low-cost transmitter package that can be installed right at the process measurement point. It’s designed specifically for water and wastewater applications in full pipes.

The all-digital AquaTrans AT868 has no moving parts and requires minimal maintenance. An onboard microprocessor uses patented Correlation Transit-Time™ technology for long-term, drift-free operation. Automatic adjustment to changing fluid properties and dynamically configured operating software simplify programming.

Transit-time flow measurement technique

The transit-time technique uses a pair of transducers with each transducer sending and receiving coded ultrasonic signals through the fluid. When the fluid is flowing, signal transit-time in the downstream direction is shorter than in the upstream direction; the difference between these transit times is proportional to the flow velocity. The AquaTrans AT868 measures this time difference and uses programmed pipe parameters to determine flow rate and direction.

Wetted or clamp-on transducers

Ultrasonic flow transducers are classified as either wetted or non-wetted (clamp-on). Clamp-on transducers are clamped onto the outside of the pipe and never come into contact with the process fluid. Wetted transducers are mounted into the pipe or flowcell in direct contact with the process fluid.

Clamp-on transducers offer maximum convenience, flexibility and a low installation cost compared to traditional flow metering technologies. With proper installation, wetted transducers provide maximum accuracy (better than 1% of reading) in most applications.

Two-channel model

An optional second channel provides the capability to measure flow in two pipes or average two paths on the same pipe for increased accuracy.

| Fluid types | Acoustically conductive fluids, including most clean liquids, and many liquids with entrained solids or gas bubbles. Maximum void fraction depends on transducer, interrogation carrier frequency, path length and pipe configurations |

| Pipe sizes | Clamp-on transducers: 12.7 mm to 7.6m (0.5 to 300 in.) and larger Wetted transducers: 25.4 mm to 5 m (1 in to 200 in) and larger |

| Pipe-wall thickness | Up to 76.2 mm (3 in) |

| Pipe materials | All metals and most plastics. Consult RS Hydro for concrete, composite materials, and highly corroded or lined pipes. |

| Flow accuracy (velocity) | 0.5% of reading (achievable with process calibration) |

| Typical clamp-on flow accuracy (velocity) | Pipe ID >150 mm (6 in): ±1% to 2% of reading Pipe ID <150 mm (6 in): ±2% to 5% of reading |

| Typical wetted flow accuracy (velocity) | ±1% of reading Accuracy depends on pipe size and installation and whether measurement is one-path or two path. |

| Repeatability | ±0.1% to 0.3% of reading |

| Range (bidirectional) | -12.2 to 12.2 m/s (-40 to 40 ft/s) |

| Rangeability (overall) | 400:1 |

| Specifications assume a fully developed flow profile (typically 10 diameters upstream and 5 diameters downstream of straight pipe run) and flow velocity greater than 0.3 m/s (1 ft/s). | |

| Measurement parameters | Volumetric flow, totalized flow and flow velocity |

| Electronics | |

| Flow measurement | Patented correlation transit-time mode |

| Enclosures | Epoxy-coated aluminum weatherproof type 4X/IP66 |

| Dimensions | Standard: Weight 0.9 kg (2 lb), size (h x w x d) 184 mm x 150 mm x 89 mm (7.25 in x 5.9 in x 3.5 in) |

| Channels | Two channels (for two pipes or two-path averaging) |

| Display | 2-line x 16 character backlit LCD display, configurable to display up to four measurement parameters in sequence |

| Keypad | Six-button internal keypad |

| Power supplies | Standard: 85 to 265 VAC, 50/60 Hz Optional: 12 to 28 VDC, ± 5% |

| Power consumption | 20 W maximum |

| Operating tempe°rature | -10°C to 55°C (14°F to 131°F) |

| Storage temperature | -40°C to 70°C (-40°F to 158°F) |

| Standard inputs/outputs | One 0/4 to 20 mA isolated output per channel, 600 Ω maximum load One frequency/pulse rate/totalizer output per channel, optically isolated, 3A maximum, 100 VDC maximum, 1W maximum, from 0.1 to 10 kHz Namur NE043 compliant |

| Digital interfaces | Standard: RS232 Optional: RS485 (multiuser) |

| European compliance | System complies with EMC Directive 89/336/EEC, 73/23/ EEC LVD (Installation Category II, Pollution Degree 2) and transducers comply with PED 97/23/EC for DN<25 |

| Clamp-on ultrasonic flow transducers | |

| Temperature ranges | Standard: -40°C to 150°C (-40°F to 302°F) Optional: -200°C to 400°C (-328°F to 752°F) See specific transducer for exact temperature range. |

| Mountings | Stainless steel chain or strap, welded or magnetic clamping fixtures |

| Area classifications | Standard: general purpose Optional: weatherproof type 4/IP65 Optional: submersible IP67/68 |

| Additional options | |

| PanaView™ PC-interface software | The AquaTrans AT868 communicates with a PC through a serial interface and Windows® operating systems. Consult the manual for details on sites, logs, and other operations with a PC. |

Reviews

There are no reviews yet.